2nd intermediate report draft about the exceptional costs

Once upon a time the build a car by Erasmus+ and eTwinning projects ...

(by Denis Leclerc le 15/12/2020)

Below is the cost of the project so far. All expenses are made in accordance with the rules of the Shell Eco Marathon competition.

Mobility 1 in EN

At the first student meeting in Caen, the aim was to give the keys to the innovative construction of a vehicle called the "Urban Concept" to compete in the "Shell eco marathon".

To this end, we have carried out several activities:

https://twinspace.etwinning.net/44941/pages/page/1476435

- The first was to model a chassis on Soliworks software and subject it to constraints to identify the reaction of various usable materials. Stretching, bending and stress tests were conducted on test tubes.

- The second was an initiation to photoelasticity in order to identify possible breakage primers.

- The third was led by an automotive designer Gregory CARRON (600 €) to explain all the steps to be taken to create a vehicle. It allowed the participating students to draw and model prototypes in polyurethane foam (23.99 €29.38 €-53.04 €). A second STI 2D class was able to participate in this activity.

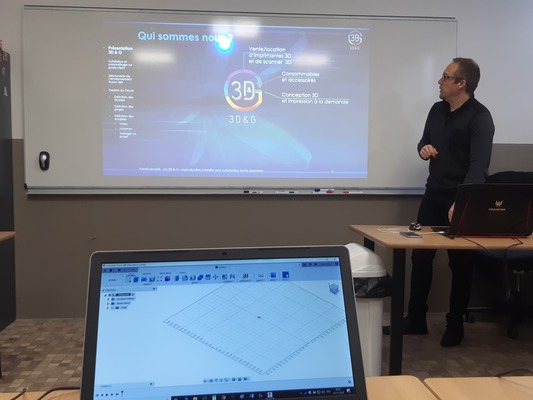

- The fourth was conducted through a local company 3D&G which trained them on the scanner and 3D printing (816 €). The prototypes previously made could be materialized on a scale reduced in 3D printing (44.64 €).

Between two mobilitys

Proposal of Logos for the twinspace and vote for the choice.

http://www.tricider.com/brainstorming/2ceU9vLxKlZ

The implementation of communication on the eTwinning platform to propose and choose chassis in terms of shape and materials for our vehicle as well as the study of the 50 pages in English of the regulations and specifications of the eco marathon.

https://twinspace.etwinning.net/44941/pages/page/263699

Participation with students in a Move2learn mobility (April 2018) allowed us to visit our Spanish partners and train them in the use of the etwinning platform in order to collaborate in thechassis construction choices.

Mobility 2 in ES

At the second student learning meeting in Seville, the vehicle began to take shape and become a reality, in the bodyshop, through welding and assembly activities.

https://twinspace.etwinning.net/files/collabspace/1/41/941/44941/files/c4ab69ba4.docx

Between two mobilitys

The chassis has been finalized and painted (48.03€) by Spanish students who take into account collaborative decisions, among other things during videoconferences between the partners. And the chassis was shipped to Sweden (122.28€).

Mobility 3 in SE

Even though the theme was ground linking a lot of chassis modification work had to be carried out by the mobility participants.

https://youtu.be/87e-YwbIGzY

Between two mobilitys

The ground link was made in Falkenberg. The brakes and steering were assembled (560.52 €), as well as the wheels and axles (310.32€).

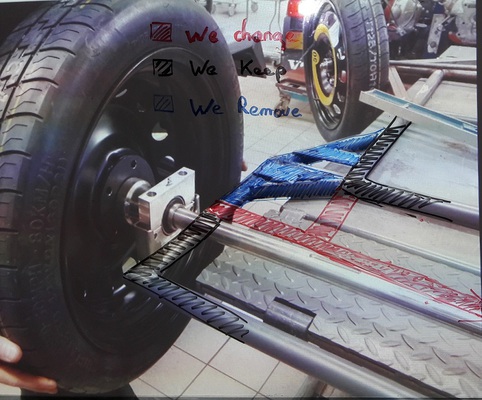

A decision about the rear wheels must be done :

https://youtu.be/v3jVvnjOLQo

The Swedish team sent the vehicle to Caen (no charges were claimed for this transport).

A collaborative vote on the choice of energy for the vehicle was organized on the twinspace. The choice of hydrogen was validated by 45% of the 87 participants. The choice of gasoline by 36% of participants shows the difficulty of changing habits and projecting in the near future of sustainable mobility.

http://www.tricider.com/brainstorming/3BXn9nNXHKd

Mobility 4 in EN

During this student learning meeting, the focus was on energy with various activities carried out.

The first involved an operation to record an electric vehicle (Zoe). This involves opening the high voltage battery circuit to the engine compartment. Although the car belongs to the French school coordinator, this project had to pay the rent of the electric battery of the vehicle,for a total of 2844 euros over the three years.

https://youtu.be/BnBXhyvEEXY?t=1

The second activity of this meeting was atraining on the technology of electric and hybrid vehicles. For this training, a magnetic kit was required (576 €). This activity also consisted of learning how to operate a fuel cell using an educational model (114.40 €).

https://youtu.be/BnBXhyvEEXY?t=60

The third activity is focused on reading the specifications and validating them with regard to the progress of the vehicle. No budget was required for this activity.

https://youtu.be/RR5Kou5SUuE

A fourth activity was proposed in the chemistry laboratory to carry out an experiment to create hydrogen with a water electrolysis. No budget was required for this activity.

https://youtu.be/qsUxeK3M0CI

A final activity was to make participants aware of the sustainable development with the help of an explosion loaned by the SDEC Energy.

https://youtu.be/IJF072nKvLA

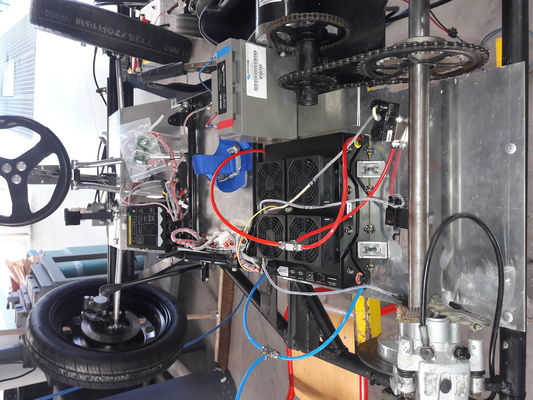

Between two mobilitys

We equipped the car with the entire kinematic chain. The first central part of the traction chain was the fuel cell (8238 €), the electric motor (118 €) whose manufacture of a support was necessary (72 €), a first version of the control unit (48 €), the accelerator pedal (31 €), the inverter (35 €), the traction chain (33.30 €) and its protective casing (43.2 €).

For the very first test with hydrogen, two bottles were invested (294 €), but as this was not enough, two more bottles were purchased (295.49 €). In order to be able to drive the vehicle, we had to buy a seat (324.41 €) with a safety harness (57.90 €).

To use the fuel cell, the purchase ofsoftware wasnecessary (500 €) and for safety a hydrogen detector was needed as well as a super capacitor for start-up (2230.1 €).

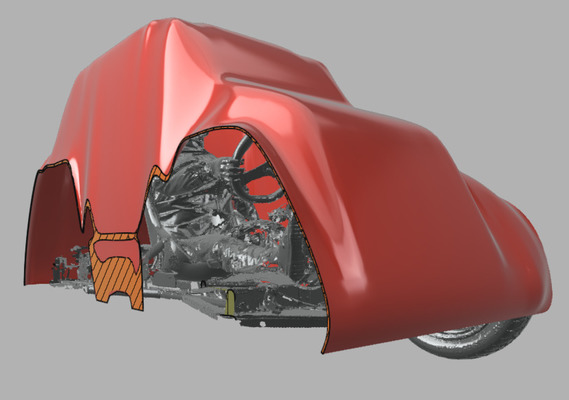

Before the vehicle was sent to Sweden, it was scanned in 3D (1123.20 €) to create a support to model the body using fusion software.

https://youtu.be/PqD3H9XWtuI

To ensure safe movement, the vehicle was placed in a wooden container that had to be built (826.90 €) and then sent to Sweden (961.64 €).

Mobility 5 in SE

At the fifth student learning meeting, the goal was to design and finalize the wiring of the lighting and signalling system.

First of all, an evaluation on Mentimenter in order to take stock of the achievements concerning hydrogen and its hygiene and safety conditions.

https://youtu.be/Vtmuuq9za6s

https://twinspace.etwinning.net/files/collabspace/1/41/941/44941/files/c0ad595d4.pdf

A conference on the operation of the fuel cell was given by the company Power cell where students from outside the school project joined us.

https://youtu.be/HZ21_IRaT-E

and a local radio station inerviewed some students about the project

https://youtu.be/TwO2tIqLPBk?t=180

Theoretical activities on wiring and safety protocols were conducted, and then the students worked at the workshop on educationaland collaborative electrical models to learn how to connectelectrical circuits.

https://youtu.be/oS3pQ7TRsjw

https://youtu.be/a-3A-CmvuCU

The vehicle was finally tested in real-world conditions and the first laps were carried out but it turned out that the hydrogen volume of the previously ordered bottles was insufficient to sustainably power the system which required the rental of a hydrogen bottle by the partners to a local company.

https://youtu.be/f45PwRId7dM

During these tests, several tens of metres were carried out on a school track, but power problems were also reported to properly tow the vehicle (the quality of the engine and controller were highlighted as well as the excess weight of the steel-made chassis).

A tour of an electric ferry connecting Sweden and Denmark was organised and we were able to visit all the technical spaces related to its propulsion system.

https://youtu.be/-RaLDitHtkE

Between two mobilitys

The Swedish team carried out the lighting and signalling system on the project vehicle.

The total cost of the activities during the mobility in Sweden and the equipment of the vehicle amounts to 1351.1 €. These costs are billed to our establishment in the form of a single invoice with the Swedish detail of each of the different expense items.

Transnational meeting in Caen

In order to imagine and model a body of the car by the students of the various transnational teams on the FUSION application, software training was required from 3D&G (894 €) to teachers so that they could transmit their knowledge to the respective students. 10 projects were successful and gave part to a collective vote on Tricider.

https://twinspace.etwinning.net/44941/pages/page/311924

The vote having elected a modern and aerodynamic body but not respecting the specifications, the body model closest to the specifications was therefore selected.

During this transnational meeting, it seemed important and necessary to have in the workshop the car in physical presence in order to also take stock of its technicalprogress. The vehicle was shipped from Sweden to France (1236.89 €). The vehicle was then sent to ES for the creation of the carbody (780.7 €).

Following the problem related to the reserve of the hydrogen bottle to mobility 5, a large bottle of 200 bar (1125.43 €) and a pressure regulator (679.2 €) were ordered from Rapid Gas in France for a total of 1804.63 €.

Mobility 6 in ES

15 days before our departure the French government declared a ban on students and teachers to carry out mobility abroad and were unable to join the Swedes who were allowed to make the trip. Covid statement?

On the third day of mobility, a state of emergency was declared in Spain and the Swedish partners had to be repatriated.

The Spanish partner in charge of the bodywork was not able to return to his school until June or to work on the bodywork and the decision of the Erasmus agency to propose the extension of the projects in progress until December is not yet in my knowledge, so I asked our partner to repatriate the vehicle. For the unloading and loading ofthevehicle, the rental of a pallet truck was necessary (209.81 €).

From the beginning of September until December 2020

On my return to school I had the unpleasant surprise of discovering the hydrogen bottle previously ordered from Rapid Gas not compliant with the regulations of the Shell eco marathon. The latter is actually far too large (1m20 height). So I made every effort to get the company to exchange it with us, but the refusal is categorical because the bottle is sealed in the name of our establishment. The manager acknowledges these wrongs as a professional but remains powerless to take it back from us. We hope to be able to use it in future projects related to this innovative energy and for which there is a general enthusiasm. In addition, we can imagine that this sum is borne by the assumption of 25% of the exceptional costs by our institution.

As a result, I had to find another supplier guaranteeing me the compliance of the bottle and I was able to buy a new bottle (718.99 €) that perfectly respected the dimensions from Messer gas.

For safety reasons, he was purchased an ABC 1kg fire extinguisher from a local Ragues company (34.63 €).

Otherwise, since the beginning of the school year, we have been committed to reducing the weight of the vehicle. For this it was completelydismantled.

A team of students redo the chassis at the same dimensional size of the original but in aluminum. To do this, tubes and plates were ordered from Arcelor Mittal (467.60 €) as well as the metal needed for welding at Leroux Brochard (53.69 €).

Another team works on wheel relief since each weighs 12 kg or 48kg for the fourth. We found despite the dimensional scarcity of the product of full wheels (rim - tires) dividing by 2 the total weight of the wheels found at Planet Eco Mobility in Caen (987.98 €).

We were able in this same company explained our power problem to tow the vehicle. Given the characteristics of our fuel cell the opinion of the electrical equipment manager is unequivocal, our electric motor and our controller are not suitable. So, he advised us to have a Brushless engine with its controller and the corresponding electrical beam (785 €).

To meet our forecast action plan, we still have to manufacture the bodywork. To do this, we asked the company 3D and G to take back the body chosen on the FUSION software to match it exactly to the many constraints submitted by the specifications of the eco marathon regulation (432 euros HT) but also to print in 3D the body at the actual size of our vehicle (7250 €HT) or a total amount of the bill of 9218.40 €

https://twinspace.etwinning.net/44941/pages/page/311924

progress of work at 11/03/2021

It will be necessary, when laying the body on the chassis to resume the junctions with fiberglass to solidify the structure (current quote ........ . . ) and apply a paint (current quote ....... .)

Of course, time has played against us and the unfavourable sanitary conditions related to the Covid will deprive us of the budget allocated to our project to complete our "urban concept" and will force our institution to bear the costs not yet planned to finalize it but the project is anchored in our institution: We will participate in the "Shell eco marathon" in the near future thanks to the Erasmus Programme and in particular to its funding and eTwinning synergy for which a partnership sticker will be placed on our vehicle for its race and promotion in our communication.

TO BE CONTINUED ....

Denis Leclerc