Ideas for our project:

- Humanoid spartan warrior with spear and shield

These were my ideas tell me if you like them.

I couldn't provide the links for the videos because some of the ideas were original.

-------------

my ideas for our projekt 1 3 4 5 6

-------------

Tracked Fan Crawler

Final design

Climate change is contributing to more frequent, severe and longer heat waves during summer months. That is why we decided to build a Fan Crawler Robot able to move around autonomously for keeping us cool.

We built an EV3 tracked vehicle using a 3-stage overall 1:27 gear ratio to power a Fan.

It can also perform line-following using a light sensor and stops at an obstacle using an ultrasonic sensor.

We decided to build the vehicle as a tracked vehicle so that it could easily move in difficult terrains. For this we used some Lego EV3 tread link components to build the continuous tank tread.

Video in operation

Gearing mechanism

Gears are typically employed in everyday devices to help transmit motion between parts of the device. Although they may come in various shapes and sizes, they typically have cut or cogs that allow them to mesh or be connected with other gears.

When two or more gears are used in tandem, a mechanical advantage is produced that can be used to change the speed, direction and magnitude of a power source (ie torque of an electric motor).

When using gears, it is common practice to gauge the transference of energy from one gear to the next by computing the gear ratio. Since the circumference of the gear is proportional to the number of teeth on gear, the gear ratio can be computed as:

Gear Ratio = # of teeth on Driven Gear / # of Teeth on Driver Gear

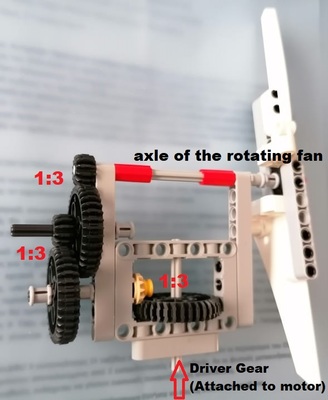

These are the gears we used to increase the speed of our fan

The bigger first one is a: Black Double Bevel Gear with 36 Teeth

The second is a: Tan Gear with 12 Teeth and Bevel

and the third is a: Black Gear with 12 Teeth and Double Bevel

A gear with fewer teeth must rotate more times when it meshes with a gear that has more teeth.

For example, for our design: the driver gear is attached to the motor and the driven gear is meshed to the driver. Our driver gear has 36 teeth, and the driven gear has 12 teeth. Computing the gear ratio yields a gear ration of 1/3. This means that for every turn of the driver gear, the driven gear turns 3 times.

For our design for maximum speed we used a gear train of 3 stages, the gear ratio for the overall gearing system is the product of the individual stages.

1st stage:

Gear Ratio = # of teeth on Driven Gear / # of Teeth on Driver Gear=

12/36 = 1:3

2nd stage: Gear Ratio 1:3 and 3rd stage: Gear Ratio 1:3

Overall Gain: 1:27

Meaning that for every 1 turn of our motor driven gear, the smaller gear where the fan is placed makes 27 turns.

(the students confirmed that by rotating slowly by hand the driver gear in the mechanism and counting the total fan rotations)

Our 3-stage gearing

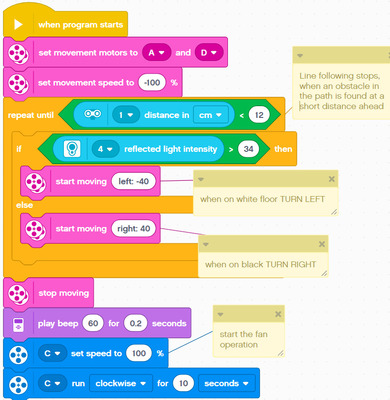

EV3 Classroom block code programmed: