Motion Transmission System

Italian team and French team will be working on different mechanisms and will be sharing their design, files and presentations.

Italian team will be developing a device that involves gears whereas French team will be working on other kind of devices such as: pulley system, crankshaft mechanism, and Geneva wheel.

Devices of Italian team:

They will be devices among bevel gears, worm gears and gear wheel.

Bevel gears are gears where the axes of the two shafts intersect and the tooth bearing faces of the gears themselves are conically shaped. Bevel gears are most often mounted on shafts that are 90 degrees apart, but can be designed to work at other angles as well.

There are several kind of bevel gears:

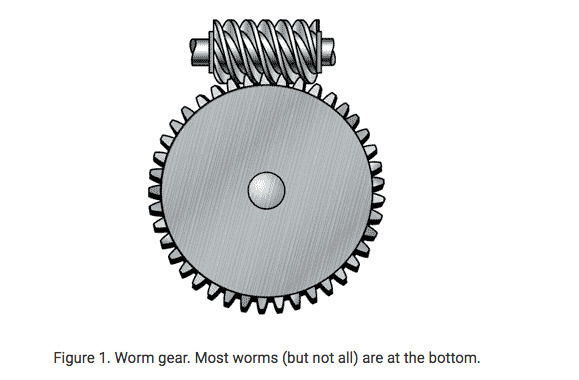

A worm gears is a gear consisting of a shaft with a spiral thread that engages with and drives a toothed wheel. Worm gears are an old style of gear, and a version of one of the six simple machines. Basically, a worm gear is a screw butted up against what looks like a standard spur gear with slightly angled and curved teeth.

It changes the rotational movement by 90 degrees, and the plane of movement also changes due to the position of the worm on the worm wheel (or simply "the wheel").

An electric motor or engine applies rotational power via to the worm. The worm rotates against the wheel, and the screw face pushes on the teeth of the wheel. The wheel is pushed against the load.

There are a few reasons why one would choose a worm gear over a standard gear.

The first one is the high reduction ratio. A worm gear can have a massive reduction ratio with little effort - all one must do is add circumference to the wheel. Thus you can use it to either greatly increase torque or greatly reduce speed. It will typically take multiple reductions of a conventional gearset to achieve the same reduction level of a single worm gear - meaning users of worm gears have fewer moving parts and fewer places for failure.

A second reason to use a worm gear is the inability to reverse the direction of power. Because of the friction between the worm and the wheel, it is virtually impossible for a wheel with force applied to it to start the worm moving.

On a standard gear, the input and output can be turned independently once enough force is applied. This necessitates adding a backstop to a standard gearbox, further increasing the complication of the gear set.

Gear wheel

Gears are used for transmitting power from one part of a machine to another. In a bicycle, for example, it's gears (with the help of a chain) that take power from the pedals to the back wheel. Similarly, in a car, gears transmit power from the crankshaft (the rotating axle that takes power from the engine) to the driveshaft running under the car that ultimately powers the wheels.

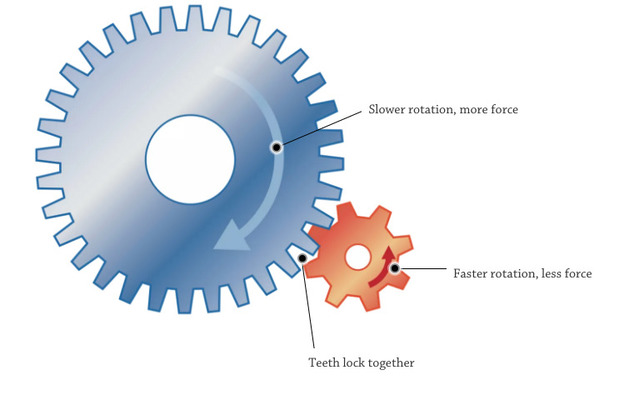

You can have any number of gears connected together and they can be in different shapes and sizes. Each time you pass power from one gear wheel to another, you can do one of three things:

- Increase speed: If you connect two gears together and the first one has more teeth than the second one (generally that means it's a bigger-sized wheel), the second one has to turn round much faster to keep up. So this arrangement means the second wheel turns faster than the first one but with less force. Looking at our diagram on the right (top), turning the red wheel (with 24 teeth) would make the blue wheel (with 12 teeth) go twice as fast but with half as much force.

- Increase force: If the second wheel in a pair of gears has more teeth than the first one (that is, if it's a larger wheel), it turns slower than the first one but with more force. (Turn the blue wheel and the red wheel goes slower but has more force.)

- Change direction: When two gears mesh together, the second one always turns in the opposite direction. So if the first one turns clockwise, the second one must turn counterclockwise. You can also use specially shaped gears to make the power of a machine turn through an angle. In a car, for example, the differential (a gearbox in the middle of the rear axle of a rear-wheel drive car) uses a cone-shaped bevel gear to turn the driveshaft's power through 90 degrees and turn the back wheels.

All the components will be designed by Solidworks and then printed in PLA.

Italian and French students will design their own device and share each other step files.

At the end both italian and french students will print twice their own model, one for themselves and one for their twinned class and send them physically by carrier-

Several meetings will be arranged to meet, present share and explain.